-

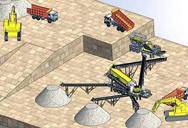

Мобильная дробилка

- щековые дробилки для строительных изделии

- мобильные дробилки на аренде Индии

- порошковая дробильная машина для продажи дробилка для продажи

- дешевая машина для мокрого измельчения

- мельница шаман текст

- мельница лугов валковая мельница

- проект дробилки в малайзии

- самая лучшая оборудование для мельницы

- Гирационная дробилка Таджикистан

- SBM конусная дробилка

- Жижиг гар дизель бутлуурын бутлуур

- Разрешения на горные дробилки

- Молотковая дробилка Дробилка Галерея

- небольшой шаровая мельница купить

- работает директором щековая дробилка

- инвестиции для каменной дробилки в Индии

- б дробилка для продажи нью джерси

- дробления в области химической инженерии

- Лучшая мобильная дробилка в мире

- Используется ball mill design kerala

<вибрационныи питатель фирмы LM

(PDF) Design of Three-chamber Ball Mill - ResearchGate

2021年1月1日 In this paper, the design method of three chamber ball mill is introduced. Comchambered with the design of Φ 3.5 × 13m three-chamber ball mill, the design

Read More

Applications of a new model-based method of ball mill simulation and design

1990年1月1日 The multi-segment ball mill model developed by Whiten and Kavetsky has been used together with an extensive range of data from operating mills to establish the

Read More

design of ball mill foundations.pdf -

\n \n The Selection and Design of Mill Liners \n. Figure 5.High low wave ball mill liner Materials The selection of the material of construction is a function of the

Read More

Design Method of Ball Mill by Discrete Element Method

2018年10月9日 Design Method of Ball Mill by Discrete Element Method collected. The diameter of the gibbsite powder was measured using a Master Sizer 2000 (Sysmex

Read More

(PDF) Grinding in Ball Mills: Modeling and Process

2012年6月1日 The paper presents an overview of the current methodology and practice in modeling and control of the grinding process in industrial ball mills. Basic kinetic and energy models of the grinding ...

Read More

(PDF) DESIGN AND FABRICATION OF MINI BALL

2016年4月25日 DESIGN AND FABRICATION OF MINI BALL MILL- METHODOLOGY Authors: Rutheravan Maria Universiti Malaysia Pahang Abstract and Figures This project is to design and fabricate the mini ball

Read More

Modeling of the planetary ball-milling process: The case

2016年8月1日 Among high-energy ball mills, the planetary is a mechanically simple and versatile device for efficient grinding. It is usually made of two or more jars, rotating at an

Read More

Used Ball Mill Design Kerala - 亚博iphone下载

Ball Mill Manufacturers In Kerala - factjeugdnoord Ball Mill Manufacturers In Kerala. 2019-12-16jk paper - a leading paper manufacturing companies mills in india, offering a wide

Read More

Ball Mill in Kerala - Manufacturers and Suppliers India

Find Ball Mill manufacturers, Ball Mill suppliers, exporters, wholesalers and distributors in Kerala India - List of Ball Mill selling companies from Kerala with catalogs, phone

Read More

Design Method of Ball Mill by Discrete Element Method

2018年10月9日 Design Method of Ball Mill by Discrete Element Method collected. The diameter of the gibbsite powder was measured using a Master Sizer 2000 (Sysmex Corpora-tion). Details of the experimental conditions are given in Table 2. Results and Discussion 1. Effects of Fins on Ball Motion in the Mill To predict ball mill grinding behavior using the dis-

Read More

MODULE #5: FUNCTIONAL PERFOMANCE OF BALL

2018年12月9日 you cannot use work index analysis for the same purpose on ball mill circuits because of the complex interactions between grinding and classification. In this module, you will learn how to relate design and operating variables to ball mill circuit efficiency through functional performance analysis*. This Introduction is seven pages long.

Read More

Ball in Kerala - Manufacturers and Suppliers India

Rs 0.10 - Rs 0.15 / Piece. MOQ : 5000 Piece(s) Color : Brown Type : Natural Vine Balls Shape : Round Feature : Eco Friendly We present a large assortment of high quality Natural Vine Balls that is available in various sizes and dimensions. Our Small Natural Vine Balls are eco friendly in nature as they are manufactured from the premium quality raw materials

Read More

Crush Plant Mini Crusher In Kerala Crusher Mills, Cone

mini stone crusher plant in kerala – beltconveyers. Mini Stone Crusher Gulin Crusher Machine. Stone Crushing Plant for 600TPH-800TPH → Mini Stone Crusher. Posted on December 7, 2011 by admin. Specifications.

Read More

Calculation method and its application for energy

2023年7月23日 its application for energy consumption of ball mills in ceramic industry based on power feature deployment, Advances in Applied Ceramics, DOI: 10.1080/17436753.2020.1732621

Read More

Market Surveys on Energy-saving Ball Mill - CSDN博客

2012年3月1日 This can enhance the milling in the granule along with the amount handled is lowered by 15-20%. Ball milling device is our traditional grinding mill and it is also certainly one of the oldest grinding mills appeared in the world. Ball milling device would be the grinding mill with simplest structure and so straightforward to operate and preserve.

Read More

Design, Construction and Performance Analysis of a 5

Since for the ball mill design we are using 80% passing, the required value of C2 for the ball mill will be equal to1.20. C3 is the correction factor for mill diameter and is given as; 𝐶𝐶3 = 2.44 𝐷𝐷 0.2 (3) However, it is important to note that C3 =0.914 vessel used

Read More

The Evolution of Grinding Mill Power Models SpringerLink

2019年1月30日 Hence, this software led to the design of lifters for ball mills and SAG mills. 5 DEM Computations with Graphic Processing Units. In the last 5 years, the three-dimensional simulation of tumbling mills is a major step forward. A full 3D simulation of a mill gives much more valuable insights into the dynamics within the mill.

Read More

(PDF) DESIGN AND FABRICATION OF MINI BALL MILL

2016年5月30日 A comparative study was carried out for an alloy of Al 50 (Ni 75 Mo 25) 50 processed by two different high energy ball mills. A SPEX and Simoloyer mill were used.

Read More

design of ball mill foundations.pdf -

\n \n The Selection and Design of Mill Liners \n. Figure 5.High low wave ball mill liner Materials The selection of the material of construction is a function of the application,abrasivity of ore,size of mill,corrosion environment,size of balls,mill speed,etc.liner design and material of constructioDESIGN CHARTS FOR MACHINE

Read More

Market Surveys on Energy-saving Ball Mill - liajones - 博客园

Ball Mill DesignBall mill design is high technologies content material, and design of ball mill sizi Market Surveys on Energy-saving Ball Mill - liajones - 博客园 首页

Read More

Grinding Mill Computer Model - AusIMM

2021年6月24日 3.3 Ball Mill Design The ball mill designs also follow the Bond/Rowlings method with comparison with other methods. Again the method of use is the same 3.4 SAG/BM Combined design This is the combined model of the SAG and BM models. The difference is that a provision in the BM model allows for the fact that finished product is in

Read More

Impact energy of particles in ball mills based on DEM

2022年1月1日 Ball mill is one of the most commonly used mills for the crushing and grinding of mineral ore. It is generally used to grind material down to the particle size of 20 to 75 μm and can vary in size from a small batch mill up to a mill with outputs of hundreds of tonnes per hour. ... Scale-up of mills is critical to the design and operation of ...

Read More

Comparative Study on Improving the Ball Mill Process

2021年2月19日 The ball mill process parameters discussed in this study are ball to powder weight ratio, ball mill working capacity and ball mill speed. As Taguchi array, also known as orthogonal array design, adds a new dimension to conventional experimental design, therefore, Orthogonal array (L9) was carefully chosen for experimental design to

Read More

Ball Mills - 911 Metallurgist

2017年2月13日 CERAMIC LINED BALL MILL. Ball Mills can be supplied with either ceramic or rubber linings for wet or dry grinding, for continuous or batch type operation, in sizes from 15″ x 21″ to 8′ x 12′. High density ceramic linings of uniform hardness male possible thinner linings and greater and more effective grinding volume.

Read More

Improvement of the structure of a ball mill with the purpose

2022年6月30日 The design and principle of operation of a ball drum mill equipped with an inclined inter-chamber partition is described. It ensures the transverse-longitudinal movement of grinding bodies in the ...

Read More

(PDF) ball mill Sheetanshu Pandey - Academia

The Pelambres mill was 21 feet diameter and 33.5 feet flange-to-flange length. Convert this length to EGL by deducting half a foot, and you have a 21 feet dia- meter by 33 feet EGL ball mill. End result: • SAG mill: 34 ft diameter by 15 ft EGL with 10 MW of motor output power • Ball mill: 21 ft diameter by 33 ft EGL with 8 MW of motor ...

Read More

Ball Mill - an overview ScienceDirect Topics

8.3.2.2 Ball mills. The ball mill is a tumbling mill that uses steel balls as the grinding media. The length of the cylindrical shell is usually 1–1.5 times the shell diameter (Figure 8.11 ). The feed can be dry, with less than 3% moisture to minimize ball coating, or slurry containing 20–40% water by weight.

Read More

Method to Determine the Ball Filling, in Miduk Copper

2023年7月25日 Dry mill feed tonnage during 8 days which ball abrasion test was performed with 5% moisture was calculated 131328 tons. Therefore, ball abrasion rate in the mill determined by Equation 10. A𝑟= At F =4003321.8 131328 =30.48 g/ton (10) In above equations: 𝑣m: 3total mill volume (m ), 𝑁: number of balls which exist in mill, 𝐴𝑏: each ...

Read More